| ||

| ||

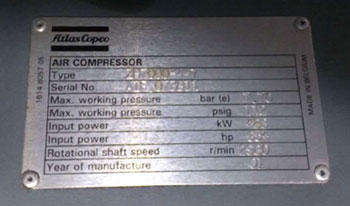

Ztechnique Oil Free FREE training videos now avaioable 2018

| ||

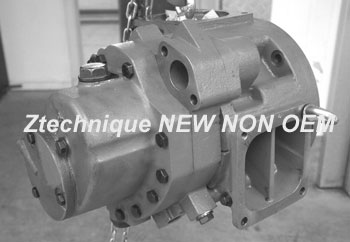

Ztechnique New Elements Presentation Video

Ztechnique NON OEM Elements for Atlas Copco 'Z' compressors from Mark Whalley on Vimeo. | ||

Great Products Begin with Great DesignBefore you can create a great product you need a great design and our Ztechnique design team have been hard at work producing our range of Ztechnique replacement air ends for Atlas Copco Z compressors.. | ||

Take a look at our casting designTake a peek inside the stage 1 design showing the compression chamber, oil seal and bearing locations, port to atmosphere, water channels and oil feeds. | ||

Moulds are made for the Ztechnique castingsUsing the latest techniques our moulds are made ffrom our own design. | ||

New Castings are used in our Ztechnique air end productsThe Importance of NO donor parts is paramount to the quality and one way shipping to far of customers around the World. | ||

Quality Testing of all our Ztechnique partsNew Ztechnique element castings are tested before and after CNC machining for quality. Several castings from our production line are cut apart to check for the correct casting process being maintained. | ||

New Timing Gears used in all our elementsThe Importance of the timing gears being new cannot be ignored.. | ||

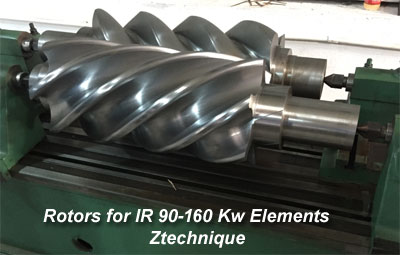

Ztechnique Rotor CuttingRotor billets are aligned from high grade steel ready for machining | ||

Rotor Cutting takes placeUsing our own profile the cutting machine works hard to make the male and female rotor sets | ||

Balancing Rotorsits essential after machining and our rotor coating is applied that the the rotors are checked for balance and adjusted as required for a the lowest possible vibration in use. | ||

Seals and BearingsOur seal assembly's are carefully selected for quality for containing the oil completely away from the compression chamber and ensuring 100% oil free air is produced. The sealing methods are very reliable combined with our journal coating procedures | ||

Wave Springs and Assembly | ||

4 Point Bearings are used in our NEW Ztechnique ElementsHigh Quality European manufactured bearings are used in the assembly of our Ztechnique elements with the cut out sections providing assess for bearing and gear lubrication. | ||

Rotor Coating ProceduresApplying the rotor coating is a multi step process with each step applied in a controlled spraying method baked at differing temperatures cycles to ensure correct bonding. | ||

Rotor clearance checks are carried outBefore and after rotor coating we check the clearances of our male and female rotors. | ||

Ztechnique Element Assembly beginsAt every stage we check alignments and ensure tolerances are met for all aspects of the Ztechnique elements | ||

Rotor Meshing & Coating the screwsHere you can see the specially coated male and female rotors meshing inside the casting after assembly. our coating has been applied to the rotors and we carefully ensure that no contact is made between the rotors with NEW cut timing gears. | ||

Checking the element assembly ZtechniqueWe dry assemble the element first to check all mating surfaces are perfect before bearings and seals are installed in the castings and on our rotors.. | ||

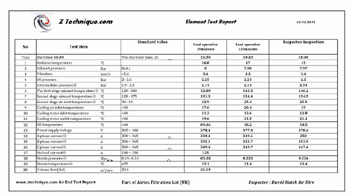

Element Test CentreOur new test centre ensures each air end is tested for output &pressure targets whist being tested for vibration SPM and seals performance. At this stage any flaw in assembly will show itself to our test engineer and will result in rejection unless the Ztechnique element meets our targets for performance | ||

100% Oil Free Air TestingWe are able to test your air quality post Z compressor overhaul with a Quality Air test to British Standards. | ||

Test Certificate Ztechnique ElementsAfter testing the element gets a full identity test cert provided showing the data recorded and your test engineers signature. For warranty purposes you must keep this certificate | ||

Packaging and Protection in TransportAfter testing each element is rust protected and tape applied to ensure no contamination or entry of foreign objects can take place before the element reaches its destination address | ||

Each Element is delivered with a USB stick loaded with your elements dataWith Each Air End supplied you get a Ztechnique Branded USB stick with your elements documents and Instructions on both video and PDF of the correct pinion fitting Instructions | ||

High Quality Branded PackagingHigh Quality crates are used to ensure no transit damage can occur and each element is accompanied with its TEST Certificate and pinion install Instructions | ||

Stock Holding Ztechnique ElementsOur large stockholding of refurbished and new ztechnique elements ensures that when you need your Z service stage quickly Air Hire can deliver.. | ||

Technical Suppot from Air HirePeace of mind is very important when you change service providers. | ||

Ztechnique Training CoursesWe run bi annual distributor Ztechnique training courses in the UK to assit distributors to sell our products.. | ||

|

Airtec Filtration & AirHire.co.uk Oil Free & Oil Flooded Compressor Spares