| |

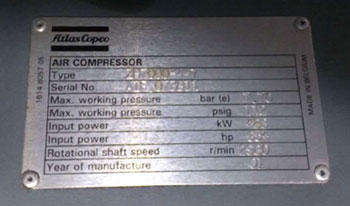

We test all customer Z elements as they arrive here and as they leave after refurbishWhen your worn element arrives here we normally carry out a running test to establish the condition of the air end that you have returned to us and output performance. | |

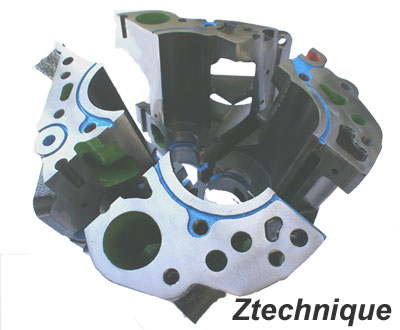

Tear down areaEach element is carefully taken down and examined before the next stage of cleaning and measurement. | |

Stage 5 Inspection areaHere we are inspecting a customer stage 5 Mk2 element prior to tear down. | |

Shot Blasting the Main Casting & Rotors before Inspection & CoatingEach Casting is carefully shot blasted to remove the old coating and paint. | |

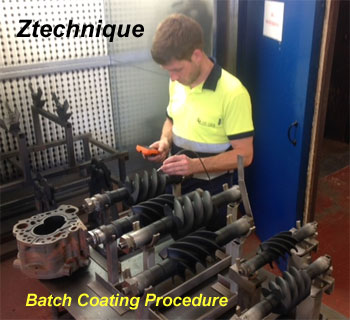

Batch Coating Rotors and Castings for refurbish of Z elementsHere you can see a batch of Z Element rotors undergoing the coating process. | |

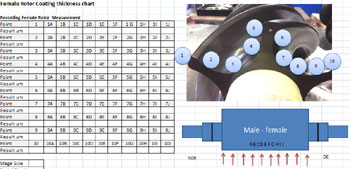

Each point checked on the Rotors and Casting is loggedHere you can see our log file for the female rotor in this case. the measurements are taken all along the flutes and inside the curvature of the flutes also. Once we are happy the coating has been applied evenly we move to the assembly stage. | |

Testing the quality of the Donor Casting is EssentialTesting the cleaned rotor casting for wear , cracks or corrosion is very Important to consistent quality of the refurbished product | |

The Importance of choosing the best NEW bearingsOur refurbished Z elements have high quality NEW bearings Installed on the entire range with the same 4 point bearing design as the SKF bearings that the OEM use. | |

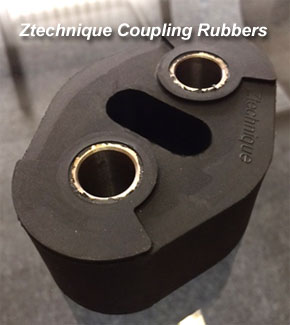

Replacing Seals and Bearings Z elementsAll worn internal parts are replaced with parts engineered and manufactured according to Air Hire's highest quality standards. As a result, you can enjoy a comparable element performance for much less than the cost of a new air end element from the OEM. | |

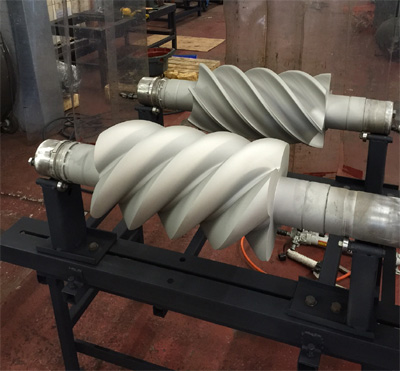

Rotor BalancingRotor Balancing is Important after cleaning re coating and each rotor is also re meshed for any high spots in our rotor meshing tool. | |

Z Service Stage Refurbishment ProcessAfter coating application and assembly we test all our elements at our test centre and check the timing gear syncro has been maintained. here you can see one of our stage 4 element rotors assembled and ready for test run | |

Assembly by Trained EngineersThe refurbished element product is assembled using fully trained engineers to high standards ready for performance testing the next stage in the rebuild process | |

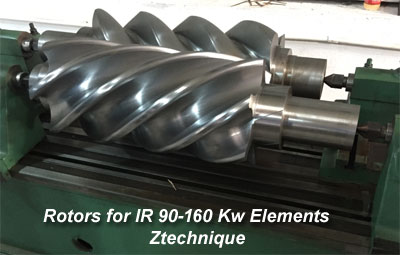

Our NEW Ztechnique elements all have new rotorsHere you can see new rotor stels about to be machined.. | |

Ztechnique rotor cutting at our facilitysInvestment in NEW rotors for all sizes of NEW Ztechnique elements is essential for quality | |

New Rotors ready for final machiningOur rotors approach final machining and are about to be checked for rotor cutting quality | |

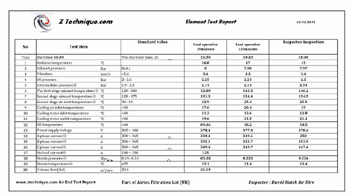

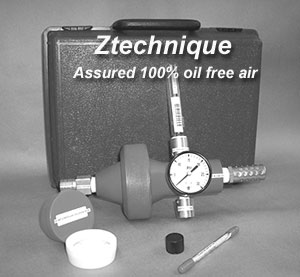

All our Elements are tested and provided with a 'Oil Free' TEST CertficateThe refurbished element is now ready to ship to our global customers having been throughgly tested at our UK element Test centre (Ztechnique) | |

100% Oil Free Air Testing is availableWe are able to test your air quality post Z compressor overhaul with a Quality Air test to British Standards. | |

Elements are carefully Packaged in Ztechnique cratesEach Element is crated with Ztechnique identification and for overseas export fumigated wood | |

Pinion Fitting Instruction and TEST ReportsEach Element we prepare is provided with a USB stick with all the relevant data from your rebuild on the memory stick | |

And when you need support we are ready for youWhenever you need us we are just a phone call away to our global customers. | |

Z Training for Distributors and CustomersIf your in need of Z training or our fitting service we can carry out both for you on request. | |

Get Inside our Ztechnique productsOur Ztechnique training courses get you to the heart of our air ends and products | |

|

Airtec Filtration & AirHire.co.uk Oil Free & Oil Flooded Compressor Spares